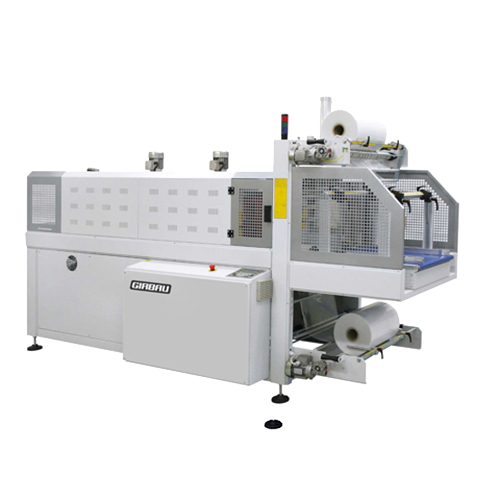

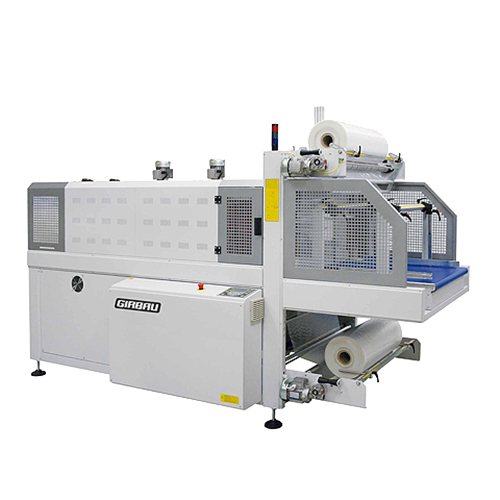

S560NA

MERKMALE

- Automatic L-seal Hood Packer

- For bagging and shrinking

BEZEICHNUNG

The S560NA L-seal hood packer incorporates automation in the process of packaging linen in order to achieve a higher productivity of up to 900 packs per hour.

It is especially recommended in industrial laundry facilities requiring the final packaging process in packs. Welding dimensions:L 430 mm wide, 260 mm high and 560 mm long.

Main advantages

- Sealing and heat-shrinking in a single operation.

- Production capacity of up to 900 packs/hour.

- Sealing using a Teflon-coated blade.

- Cooling of sealing system with permanent liquid closed circuit.

- Packing level and support reel independently adjustable according to the size of the package.

- Automatic hood re-opening.

- An automatic work cycle, continuous cycle sealing system (the automatic lowering of the sealing arm can be programmed at intervals of time) - sets the work pace for the operator.

- Or lowering the sealing frame using a button.

- Automatic expulsion of pack made, using a motorised mesh (doubling the productivity of a conventional hood machine).

- Machine status.

- Number of packs produced by an electronic pack counter.

- Electronically adjustment of the sealing temperature.

- Shrinking delay for sensitive films.

- Adjustment of the shrinking time.

- Adjustment of the forward movement of the motorised belt (greater performance).

- Adjustment of the temperature of the shrinking chamber.

- Possibility of scheduling up to 10 different work cycles.

- Troubleshooting.

Laden Sie Ihre Broschüre herunter