"The first rule of any technology used in a business is that automation applied to an efficient operation will magnify the efficiency."

Embracing the new era of laundry sorting

Are you struggling to find operators for your laundry?

Facing challenges in sorting soiled items accurately and efficiently?

Seeking to enhance the hygiene and safety standards of your laundry?

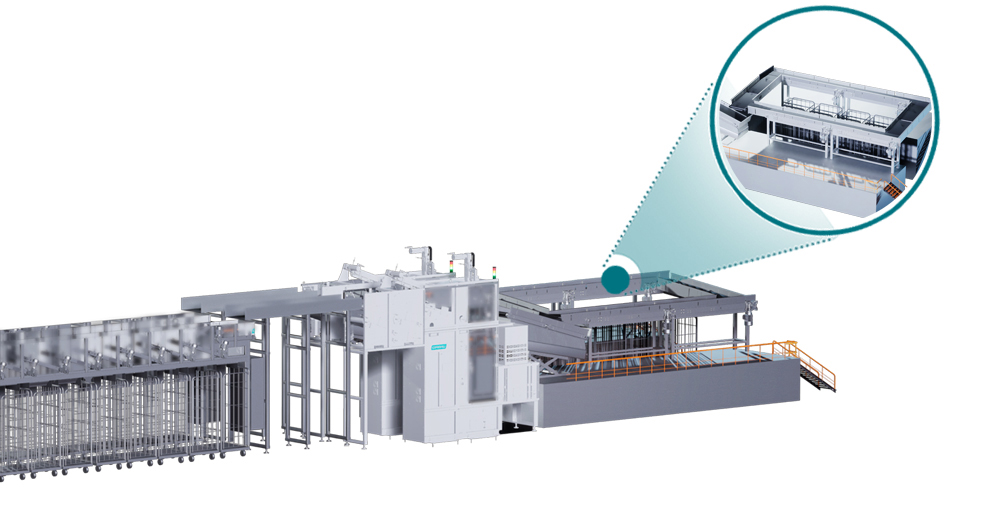

Discover Sortech, the revolutionary automated sorting solution from Girbau. Through cutting-edge RFID technology, Sortech individually identifies soiled items, reads their chips, and automatically categorizes them, offering a highly configurable system adaptable to various productivities and spaces.

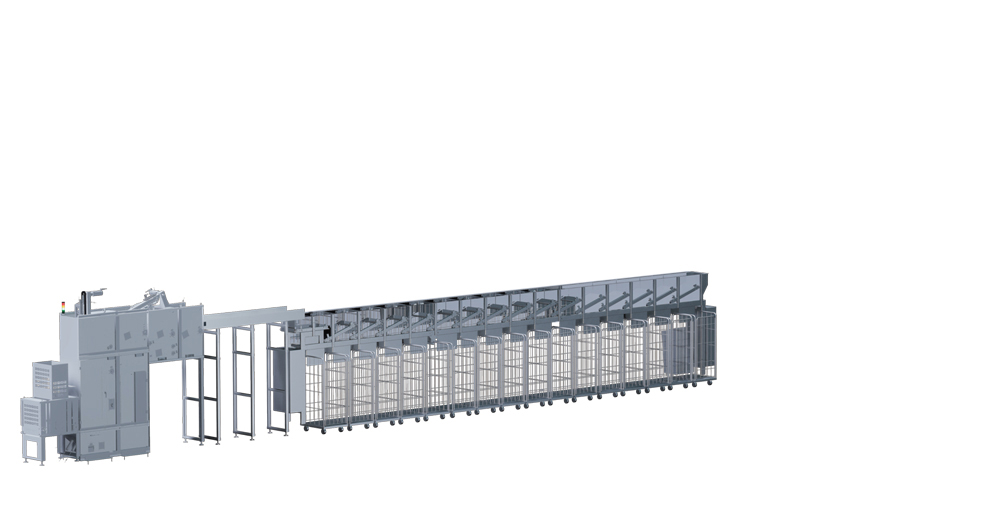

Sortech

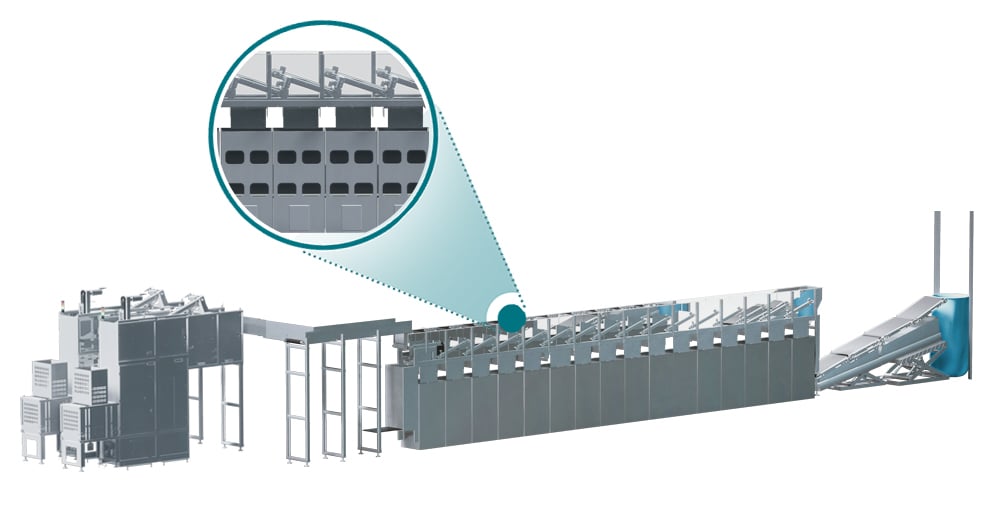

1 PKS + 1 Sorting lane

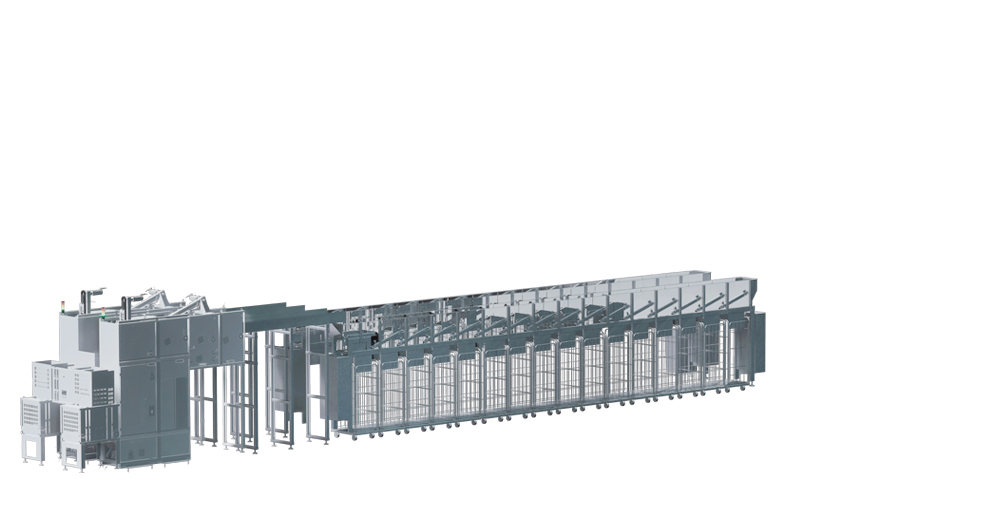

Sortech

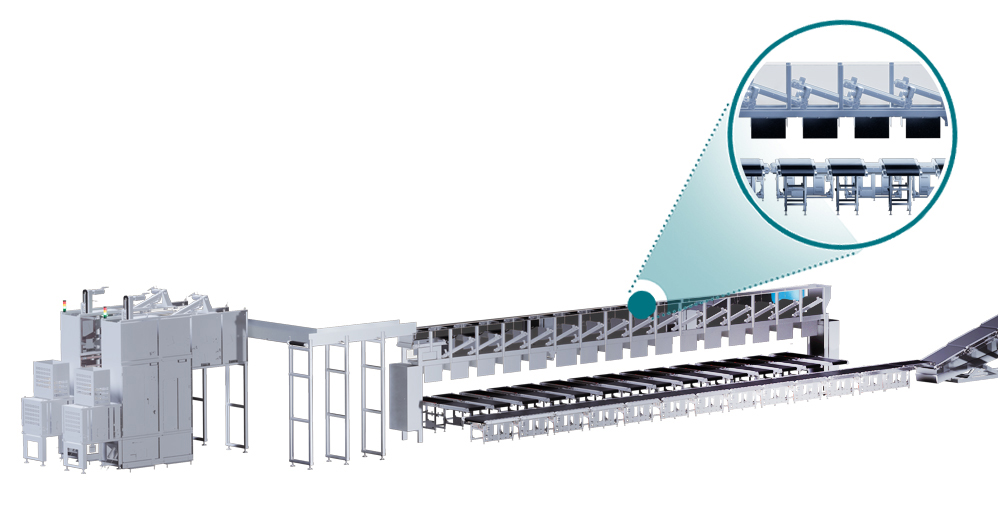

2 PKS + 2 Sorting lanes

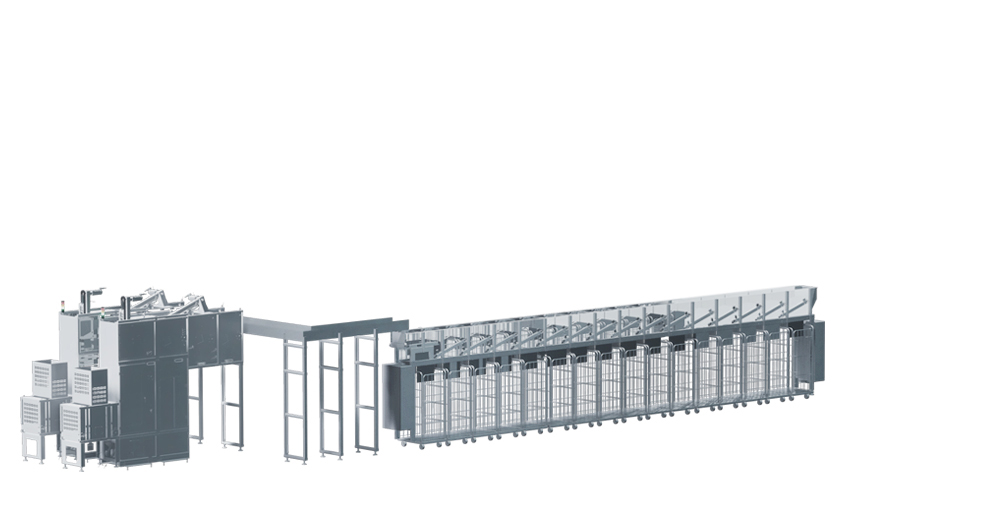

Sortech

2 PKS + 1 Sorting lane

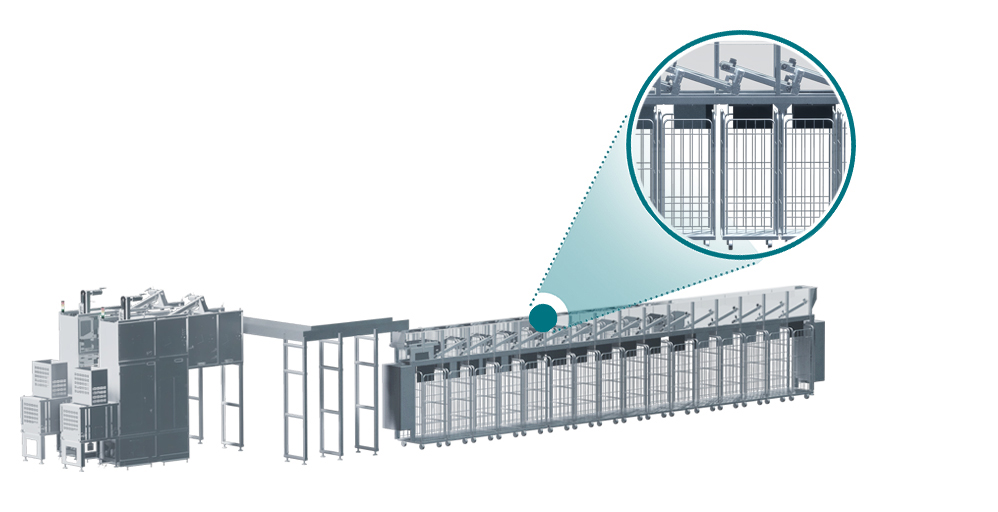

Sortech

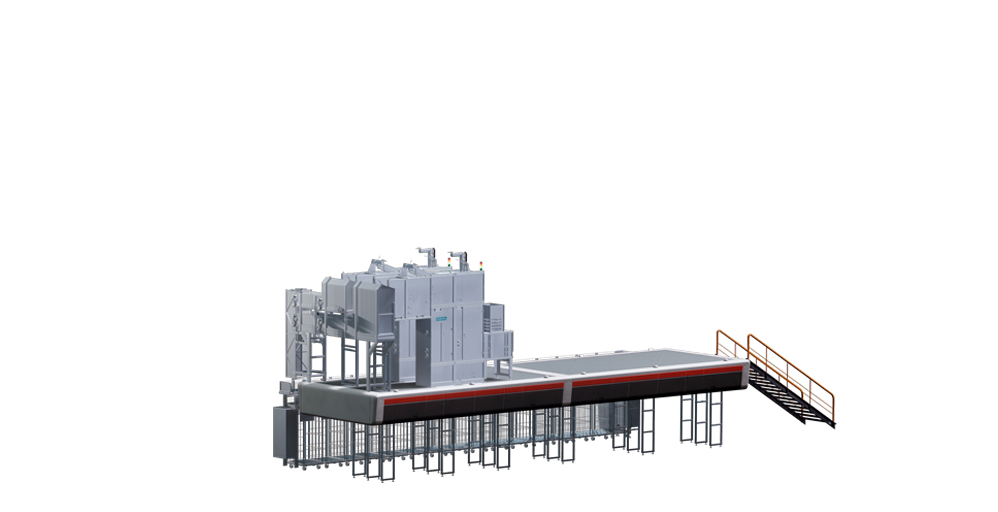

Sorting into trolleys

Sortech

Sorting into weighing silos + Bag rail system

Sortech

Sorting into weighing conveyors + Bag rail system

Sortech

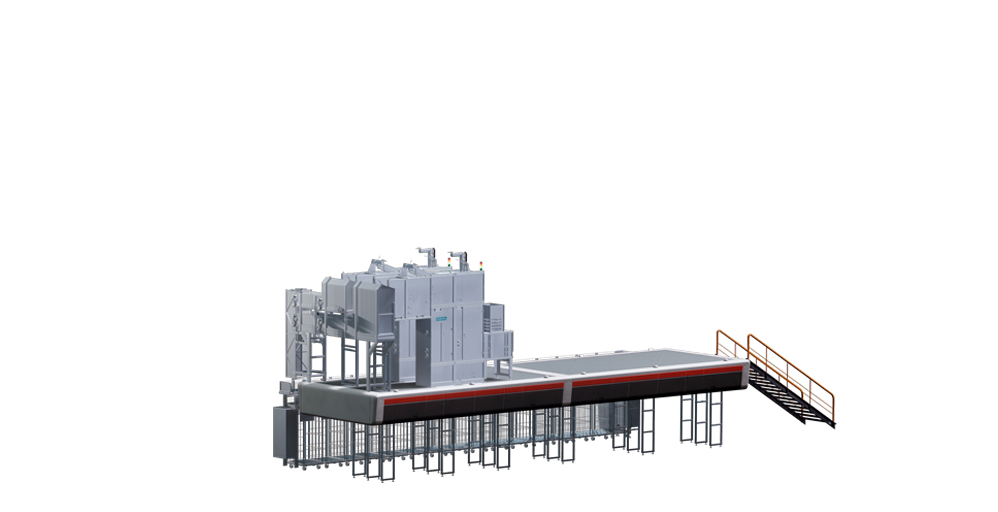

Customized layouts

Sortech

Customized layouts

Sortech

Combined with manual sorting

Feeding

Picking

Scanning

Identifying

Sorting

Ready to wash

Upgrade to RFID laundry technology

Sortech has a simple and reliable design to ensure non-stop production and affordable maintenance for all laundries working with RFID technology. Among other advantages, Sortech has multiple visual aids to reduce downtime, access for easy maintenance and touch screens for easy interaction. A 100% configurable solution with different sorting options and the ability to detect and set aside items containing dangerous objects or items with defective RFID chips.

Sortech offers tailor configurations and layouts to match diverse production requirements.

A Sortech system with two picking stations connected to a single sorting lane can achieve productivity levels of up to 1,800 pieces/hour, equivalent to the output of two operators per shift.

Additionally, Sortech incorporates visual aids to minimize downtimes and maximize productivity.

In an environment where finding staff is increasingly challenging, prioritize the well-being of your operators by automating complex and demanding tasks, such as sorting soiled linen.

Sortech prevents direct operator contact with contaminated items, elevating safety and hygiene standards.

Moreover, Sortech can be equipped with a scanner to identify garments containing dangerous items, further enhancing safety protocols.

Contrary to complex designs with expensive components, Sortech features a simple design with common and standard components, ensuring quick and cost-effective maintenance.

This is easily seen in the picking stations, which have been designed with simple and effective mechanical guides for the clamps, supported by a mechanical pusher at the bottom to guarantee the presence of the garments at the clamps' pick-up point. This eliminates the need to maintain and calibrate complex components such as cameras or axis with 3 degrees of freedom.

Multiple access points and drawers facilitate seamless maintenance procedures.

Thanks to its high configurability and customization, Sortech is incredibly versatile:

· Configurable with as many picking stations as needed for desired productivity.

· Offers multiple sorting options and categories.

· Adapts to different layouts and geometries, fitting into tight and complex spaces.

· Capable of handling different types of items, including larger linen like duvets, duvet covers, or king-size sheets.

Download your brochure