“It is not the strongest or the most intelligent who survive,

but the one that best adapts to changes. "

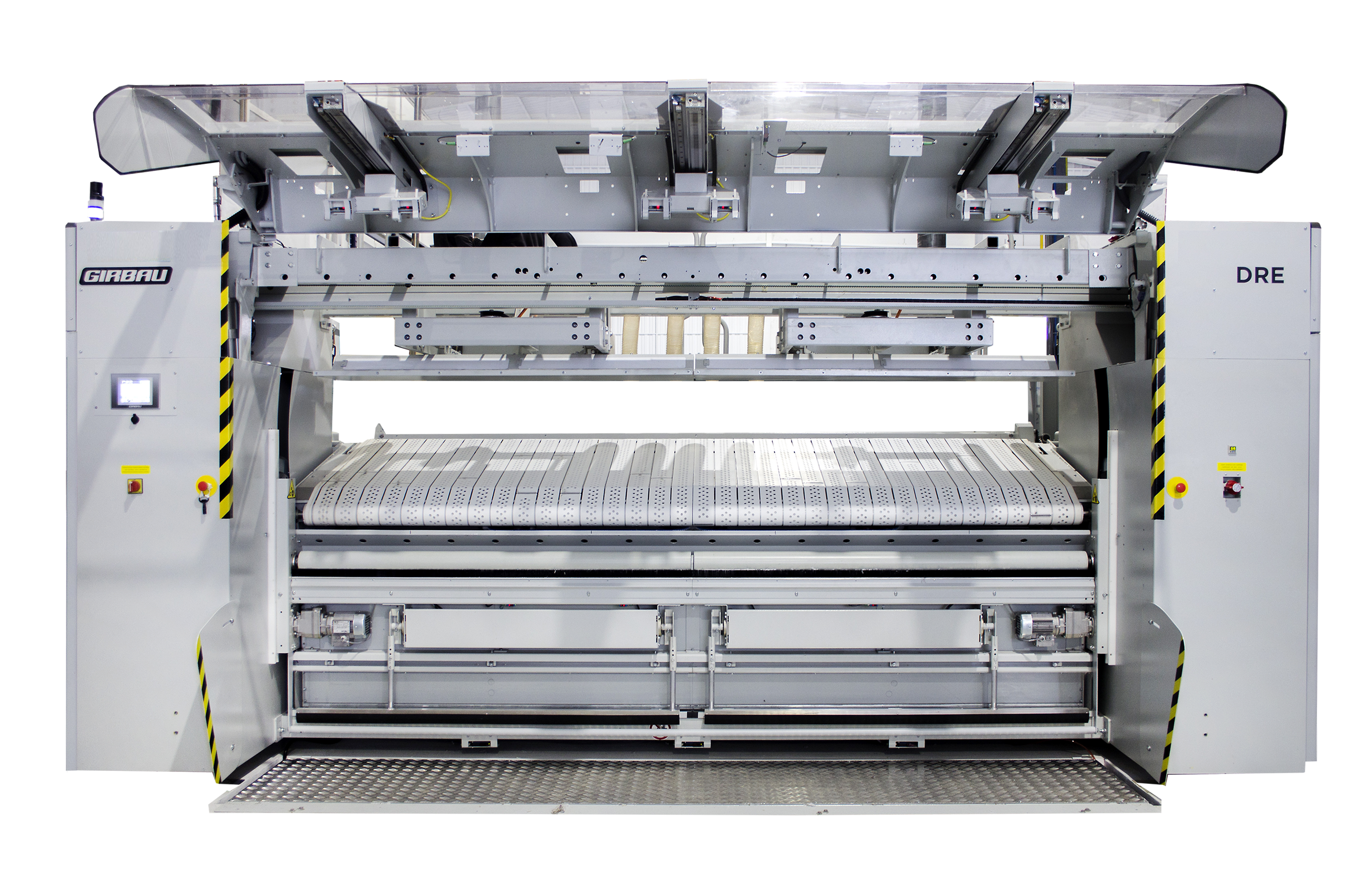

When the size of linen is no longer a problem

Are all your linens the same weight and dimension? The answer is no.

Why is it then, that when using some feeders, changing linen types is a problem?

Introducing a range of DRE Feeders designed to feed linen, of a wide variety of types, weights and dimensions, at high speed into a corresponding ironer.

Now you can switch item types - from a napkin to a King sheet, for example - without having to change the program.

BIG MANUFACTURES

Automatic mode

SMALL MANUFACTURES

Manual mode

Efficiency

Quality

High speed productivity

Programmable control

Easy maintenance

Speed with the highest quality

With up to 4 loading stations and 4 server clamps, the DRE feeder achieves a throughput of up to 1,300 pieces / hour in 1 lane, and up to 1,700 pieces / hour in 2 lanes. A new clamp assembly design facilitates the transfer of linen from the feeding station to the server simply and quickly, with fewer components in the transfer area. Plus, the bearings and guides are maintenance-free.

The bottom line: Improved quality and production!

Technology at the service of productivity

Girbau’s research and development team has worked hard to improve the servo-control, a system that handles the transfer of linen. The servo-controlled vacuum feeding on a horizontal table and the increased precision, speed and flexibility of the transfers create a 12% reduction in compressed air consumption. All with one goal: to make your business stand out for its excellent level of quality, and for a profitable bottom line!

Convinced that people are at the heart of any laundry operation, we have designed DRE feeders with your team in mind: The operator stations are adjustable to fit the height of each operator and to facilitate accessibility to the control buttons. Additionally, feeding starts automatically when the presence of linen is detected.

Thus, we eliminate downtime, maximize feeding rate and ensure maximum safety and protection: safety mat, visibility from the outside, mechanical locking of automatic cylinders, etc.

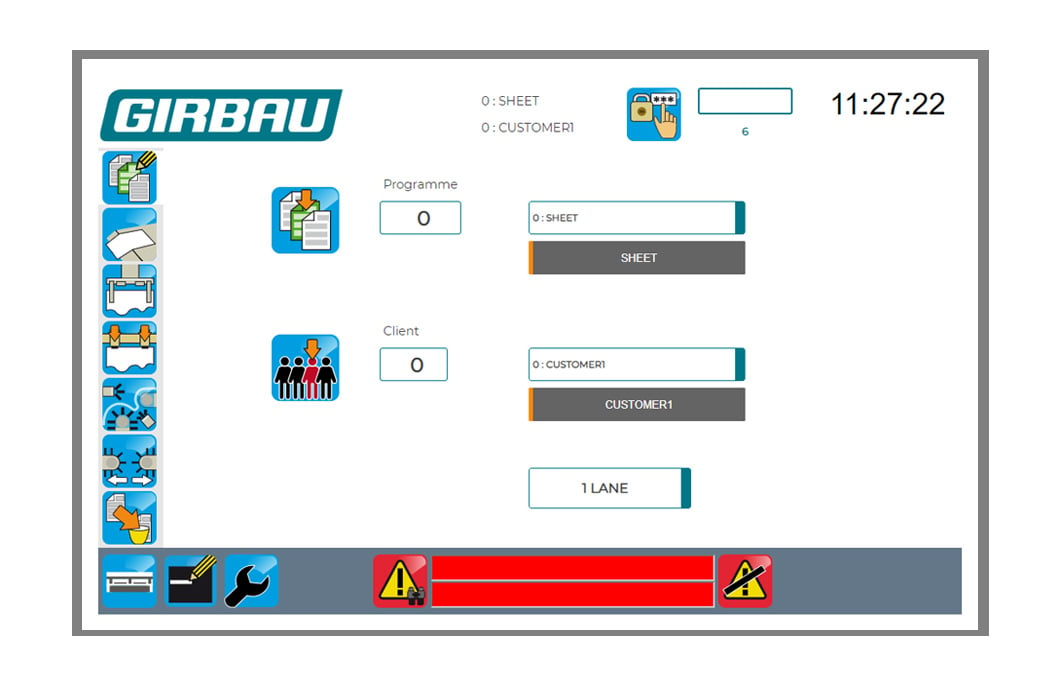

The DRE's large touchscreen displays an easily understandable icon system. While the DRE can operate independently, it also networks seamlessly with the other machines and brands in the ironing line, including the ironer, folder and stacker.

Learning to use a feeder has never been easier.

Accessibility and productivity control

The DRE’s cleaning and maintenance is easy thanks to quick access from the side panels and front doors. This reduces maintenance costs and downtime.

All main components are accessible from the DRE’s side cabinets, while the pneumatic feed table is accessible, and can be cleaned, from the rear of the DRE.

Optional Counters

An optional counter system for real-time production is available on the DRE. The counter tracks production on each station independently.

Maximum safety for your operators

The DRE features protective accessories and easy visibility from the outside. Clear visibility eliminates the need to remove guards or open covers.

Download your brochure