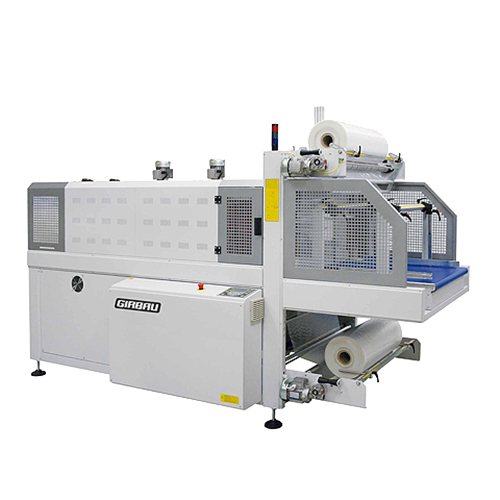

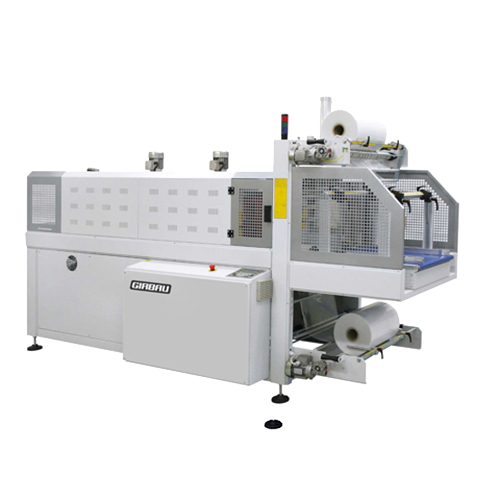

BP1102AS

CARATTERISTICHE

- Automatic front-loading Shrinkwrapper for Large Formats

- Shrink tunnel included

DESCRIZIONE

The BP1102AS automatic front-loading shrinkwrapper adapts the in-line packaging to packages of large size items: quilts, blankets, towels or rugs.

Automatic loading via conveyor allows rapid input of the collected linen. The maximum packet length can reach 2 metres (2,000 mm) with a maximum production of up to 12 packs per minute or 720 packs per hour. Technical specifications:

- Shrinkwrapper for working with large-sized products, groupings of bedspreads, blankets, towels, rugs…

- Compact structure, with support stands.

- Automatic product loading by conveyor belt, suitable for connecting onto production line.

- 1,070 mm wide sealing bar.

- Pneumatic sealing bar, with cold blade film cutting.

- Maximum length of pack 2,000 mm.

- Maximum production capacity: 12 packs per minute.

- Feeding conveyor with speed adjustment controlled by means of an inverter.

- Motor-driven upper unwinder, controlled by an invertir.

- Motor-driven lower unwinder.

- Metric scale for centring the reels.

- Operates by reading the product by photocell or by length of pack.

- Operates in automatic mode, semi-automatic mode or free passage.

- Digital control panel with Flextron electronics.

- 10 different working cycle memories.

- Automatic bar height control.

- Adjustable input conveyor and tunnel conveyor.

- Temperature of the clamp (sealing bar).

- Automatic shutoff system.

Process statistics:

- Pack counter.

- Pack length detection.

- Instantaneous production.

- Machine performance.

- Control of anomalous packs.

SHRINKING TUNNEL:

- Double chamber shrinking tunnel, to ensure good finishing in large-sized products.

- Tunnel conveyor controlled by inverter (speed adjustment).

- Adjustable tunnel air flow using independent deflectors located at the input and output of the tunnel.

- Includes a turbine to cool the pack at the tunnel output.