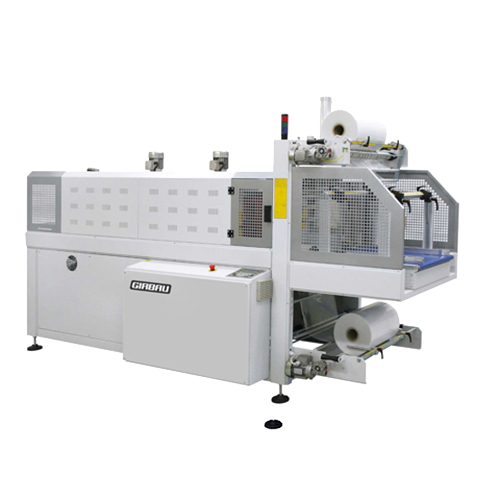

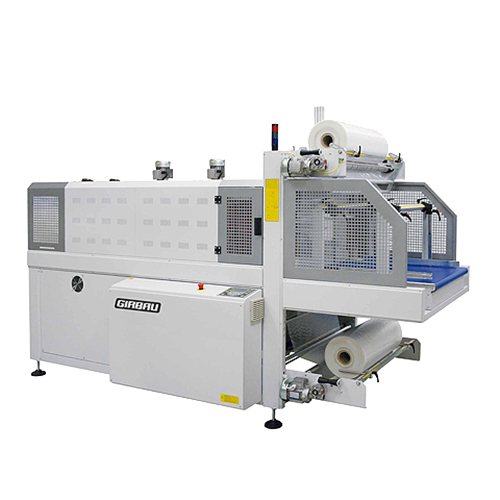

BP802AS

CARATTERISTICHE

- Automatic front-loading Shrinkwrapper Compact, tunnel included.

- Suitable for connecting into a production line.

DESCRIZIONE

Compact format with tunnel included, making this proposal a suitable packaging machine for inclusion in the production line.

Packaging is done independently by automatic loading onto the conveyor belt, which can accommodate large, indivisible packages.

Maximum pack length can reach 2 meters (2,000 mm) with a maximum output of 20 packs per minute or 1,200 packs per hour.

Technical features.

Compact structure with support stands.

Automatic product loading by conveyor belt, suitable to be connected to the production line.

Machine suitable for working with large packages (indivisible) and all types of groupings previously packed on trays.

760 mm wide gripper.

Pneumatic sealing bar, with cold blade film cutting.

Maximum pack length 2,000 mm.

Maximum production capacity: 20 packs per minute.

Feed belt with inverter-controlled speed regulation.

Motor-driven upper unwinder, controlled by an inverter.

Motor-driven lower unwinder.

Metric scale for reel centering.

Operates with product reading by photocell or by package length.

Operates in automatic, semiautomatic or free-pass mode.

Digital control panel with Flextron electronics.

Parameters adjustable from the panel

10 memories of different working cycles.

Automatic bar height control.

Adjustable inlet conveyor and tunnel conveyor.

Clamp (sealing bar) temperature.

Automatic shutdown system.

Process statistics.

Package counter.

Package length detection.

Instantaneous production.

Machine performance.

Control of abnormal packs.

SHRINK TUNNEL.

Double chamber shrink tunnel to ensure production up to 20 packs per minute.

Inverter-controlled tunnel conveyor (speed control).

Tunnel airflow adjustable by independent baffles located at the tunnel inlet and outlet.

Includes a turbine to cool the pack at the tunnel exit.